Materials of Fences:

Fence Fittings:

- Fence Staple

- T Steel Fence Post

- Y Fence Post

- U Fence Post

- Fence Gates

- Barbed Wire

- Razor Wire

- Bird Spikes

- Fence Binding Wire

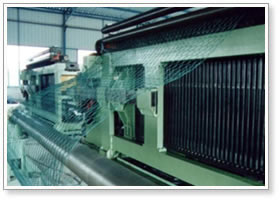

HDG Mesh Fences

HDG is also known as hot-dip galvanizing. Hot dip galvanized steel components are immersed in molten zinc liquid metal coating layer obtained in a way. In recent years, with the high-voltage transmission, transportation, communications industry rapid development of increasingly high requirements for protection of steel parts, hot dip galvanized demand is also increasing.

HDG mesh fences offers great propertie due to its processing.

The hot-dip galvanizing layer protective performance

Usually galvanized layer thickness 5 ~ 15μm, and 35μm hot dip galvanized layer is generally above, or even up to 200μm. Galvanized coverage is good, dense coating, no organic inclusions. As we all know, atmospheric corrosion resistance of zinc mechanism with mechanical protection and electrochemical protection, under the conditions of atmospheric corrosion of zinc in the surface layer of ZnO, Zn (OH) 2 and basic zinc carbonate protective film, to some extent mitigate the corrosion of zinc, which protective film (also called white rust) will form a new damage layer. When the zinc layer is severely damaged, threatening to iron matrix, the zinc on the substrate to produce electrochemical protection, zinc standard potential-0.76V, iron standard potential-0.44V, zinc and iron to form micro-batteries as the anode is dissolved zinc, iron as the cathode is protected. Clearly galvanized iron to the base metal is superior resistance to atmospheric corrosion galvanized.

The hot-dip galvanizing layer formation process:

Hot-dip galvanizing layer formation process is an iron matrix and the outermost layer of pure zinc is formed between the iron - zinc alloy process, the surface formed when the hot-dip iron - zinc alloy layer, which makes the iron very pure zinc layer good combination, the process can be simply described as: When the workpiece immersed in the molten iron liquid zinc, first formed at the interface of zinc and α iron (body-centered) solid solution. This is the base metal of iron dissolved in the solid state to form a crystalline zinc atoms in the two metal atoms are fused, the attractive forces between atoms is relatively small. Therefore, when the zinc in the solid melt reaches saturation, zinc, iron, mutual diffusion of atoms of two elements, spread to (or called penetration) of zinc in the iron matrix in the matrix lattice atoms migrate gradually forming an alloy with iron, and the diffusion to the molten iron in molten zinc and zinc on the formation of intermetallic compounds FeZn13, sink galvanized pot, that is dross. When the workpiece is removed from the liquid when the dip zinc surface layer of pure zinc, hexagonal crystals. The iron content is not more than 0.003%.